Soap Stamping Machines - Small Soap Machines

The small soap presses (also called soap stampers) are studied to produce stamped soap bars with different shapes (rectangular, oval, round) starting from the extruded soap bars.

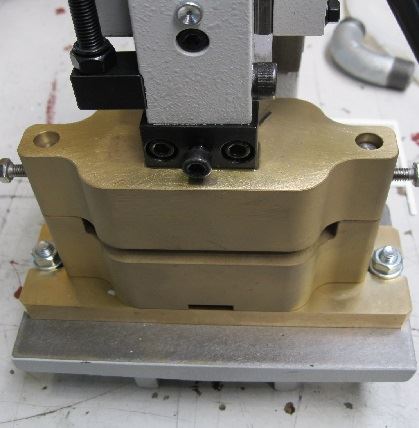

Our Soap Presses includes Including, one Die-set (soap mold), as per Customer Specifications, composed with: 1 lower and 1 upper moulds with centering pins, as per Customer Specifications (weight, dimensions and shape).

To produce Stamped soap bars, we supply two different types of small Soap Presses:

- The Manual Soap Press MSP-500 is designed to stamp bandless oval toilet soap bars and small round or rectangular Hotel soap bars. This machines has a Force able to produce soap bars up to 75 grams.

- The Pneumatic Soap Press PSP-1000 is designed to stamp banded and bandless toilet and hotel soap bars. Thanks to the pneumatic cylinder this professional soap press is able to stamp soap bars up to 150 grams.

- The Pneumatic Soap Press PSP-2000 is designed to stamp banded and bandless toilet and hotel soap bars. Thanks to the pneumatic cylinder this professional soap press is able to stamp soap bars up to 250 grams.

- The Pneumatic Soap Press ASP-30 is the first Automatic Stamper designed for a small soap finishing line. It is designed to stamp banded and bandless toilet and hotel soap bars. Thanks to the pneumatic cylinder this professional soap press is able to stamp soap bars up to 250 grams.

On request we also supply additional soap moulds (soap die-sets) to produce different shapes of soaps.

MANUAL SOAP PRESS MSP-500

TECHNICAL SPECIFICATIONS:

- Manual soap press

- Stamping by manual lever

- Maximum Stroke with Mould Assembled: 100mm.

- Anti-rotation slide for precise upper die movement.

- Adjustable bottom dead point o the upper die, to regulate the right distance between the upper and lower moulds.

- To produce single soap up to 75g

PNEUMATIC SOAP PSP-1000

TECHNICAL SPECIFICATIONS:

- Semi Automatic soap press

- Stamping by pneumatic cylinder

- Maximum Stroke with Mould Assembled: 100mm.

- Anti-rotation slide for precise upper die movement.

- Adjustable bottom dead point o the upper die, to regulate the right distance between the upper and lower moulds.

- Panel with push buttons

- To produce single soap up to 150g, or two soaps per time up to 75g

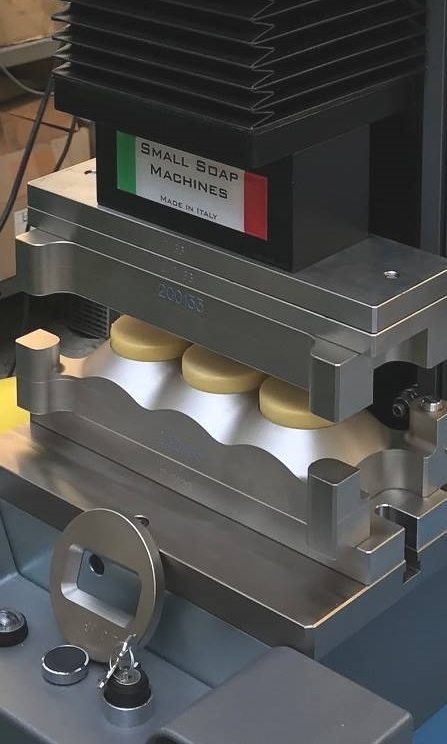

PNEUMATIC SOAP PRESS PSP-2000

TECHNICAL SPECIFICATIONS:

- Semi Automatic soap press

- Stamping by pneumatic cylinder

- Maximum Stroke with Mould Assembled: 100mm.

- Anti-rotation slide for precise upper die movement.

- Adjustable bottom dead point o the upper die, to regulate the right distance between the upper and lower moulds.

- Panel with push buttons

- To produce single soap up to 250g, or two soaps per time up to 125g, or three soaps per time up to 75g

AUTOMATIC SOAP PRESS ASP-30

TECHNICAL SPECIFICATIONS:

- Desk-Top Automatic Pneumatic Soap Press suitable for stamping any shape from hotel size to 250grms.

- Up to 30 spm depending on the size.

- Automatic soap infeed

- Stamping by pneumatic cylinder.

- Automatic soap discharge

- Safety cover openable by air piston.

- Perfectly matchable with our cutting machine EPC-60-DKT or EPC-120.

- Electric consumption: 0.3 kW.

- Electric voltage 230, 50/60hz, single phase.

- Air needed up to 6bars, 200 l/m.